What Materials Can You Carve and Engrave with a CNC Router?

Having fun carving and looking for new materials to play with? One of the best ways to optimize your CNC router is to carve, etch and/or engrave names, images, and patterns on all sorts of products. It’s creative, fun, and provides that personal and unique touch.

Wood isn’t the only material you can carve with your CNC router. In fact, there are tons of materials you can experiment with, which we’ve rounded up right below.

Let’s have a quick walkthrough on what CNC carving is all about.

Carving and Engraving with a CNC

As you might already know, carving and engraving are techniques that create patterns and shapes by removing portions of the material’s surface. Both are incredibly meticulous and could take forever to finish if done by hand.

A CNC router extends an artist’s capabilities significantly by automating the carving process. It comes with industry-standard design software for designing projects and control software for easy hands-off operation.

So what are some of the materials you can carve, etch, and engrave with a CNC router?

1. Carving Wood with a CNC Router

Wood tops the list for being the most commonly used material for CNC projects. It’s easy to work with and readily available. All types of wood are welcome, but some of the most popular are:

Maple

Walnut

Cherry

Cedar

Cypress

Here are some wood carving projects from our very own customers:

2. Carving Plastics with a CNC

CNC machines work great when machining plastics and acrylics as well. You just have to keep your tools sharp and running at just the right speed to make sure everything is kept steady.

For beginners, it’s best to start with hard plastics since soft types can be too fragile and require care and patience.

Here are the best types of plastics that Digital Wood Carver recommends:

Acrylic

Plexiglas

Polycarbonate

ABS

Delrin

Here are some plastic carving projects from our very own customers:

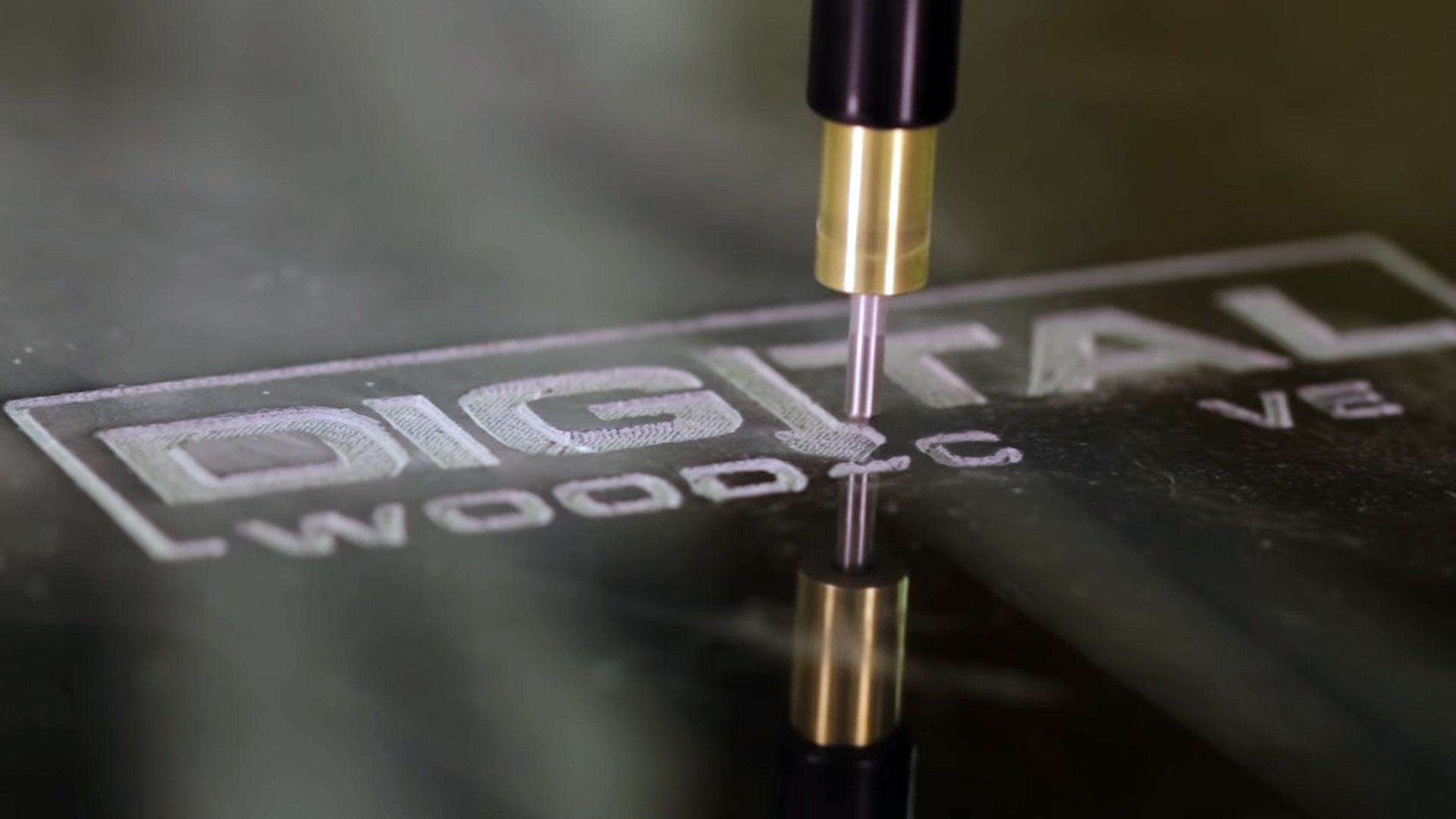

3. Carving Non-Ferrous Metals with a CNC Router

Soft metals can also be used for carving and engraving. Since they are a lot harder than wood, you will need to be more careful with your design and bit selection, and it may not have the flexibility that wood offers. Don’t panic though! You can always opt for engraving as an equally stylish alternative.

Some examples of non-ferrous metals are the following:

Aluminum

Gold

Copper

Silver

Brass

Though a CNC router is more often used for cutting wood and plastics, it can be used for cutting aluminum (or other non–ferrous metals). For cutting non-ferrous metal it is not so much that you need a different router but that you will need to use it differently. The exact abilities of a machine will vary with size, rigidity and power.

Here are a number of differences to keep in mind:

The “sweet spot” for metals’ optimum speeds and feeds is much smaller than that of wood. If you don’t stay within this optimum bracket, your cutters will begin to wear out much quicker or break frequently and your surface finish will be low quality.

Some metals, such as aluminum, have a tendency to stick to the cutting tools. Build-up of aluminum deposits on the edges of cutting tools and result in the bit welding itself to the metal. It order to cut successfully with aluminum you should:

use a feeds and speed calculator

use carbide coated bits

clean chips and deposits regularly and thoroughly

make more passes at shallower depths to make cleaning easier

use fewer flutes and increase cut width

don’t reduce the speed rate too much

use a mist to lubricate to help prevent chips from sticking to the cutting edges

Trying out a variety of materials on your CNC boosts your flexibility and skill as a woodworker and maker. We highly encourage you to explore other materials as well like foam, marble, tile, glass, and beyond!

What Router Bits Do I Need?

Provided your CNC is robust enough, the proper selection of cnc router bits will help you carve on various materials successfully.

There are three common types of CNC machine cutters: V-bit, ball end mills, and engraving bits.

V-Bit for CNC Carving

V-bits are your common sharp-pointed cutters. It often has a steel base and edges made of carbide. V-bits come in all sizes and angles depending on your preference, but smaller angles are best for more complex detail work.

Ball End Mill Bits

The ball end mill’s dull tip is both its asset and downside. Used for removing large sections of material quickly, it is characterized by a spiral tip that keeps the cutter durable and suitable for long-term use. However, it is not as sharp as your V-bit and engraving cutters, and isn’t used for fine line detail work. That being stated, the ball nose end mill is the “go-to” bit for 3D finish detail carving. The typical and most common size and type of ball end mill is 0.125 Tapered ball nose end mill.

Engraving Bits

An engraving cutter is a twin of V-bit cutters, but smaller and made out of pure carbide. Cheaper ones are made with a single-cutting flute, while more versatile (and pricey) ones often feature a double-cutting flute for optimum efficiency.

A CNC router opens doors to both solo entrepreneurs and established businesses, and the opportunity to learn carving and engraving is only one of them.

So feel free to explore different materials. Everyone has the freedom to each their own preferences. Success may not be guaranteed at first, but the more experience you gain, the higher your chances of understanding how best to work with different materials to make projects your customers will love!

For access to a complete list of materials that can be carved or engraved with a CNC, you may reach out to us anytime at Digital Wood Carver.