Retired Sheriff Launches Successful CNC Business with ZERO Experience

See how Mike scaled up his woodworking business with a commercial DWC5100 CNC Router and a laser… with ZERO experience with CNCs!

When Mike Bowlby retired from the Sheriff’s Department, like most retirees do, he and his wife started looking for meaningful ways to keep busy – preferably one that was highly-rewarding, but without the stresses and obligations of a regular job.

They found what they were looking for by starting a CNC woodworking small business with the help of Digital Wood Carver.

Their journey started with a single DWC2440 CNC Router.

Mike began with carving police badges, and by now he’s sold hundreds of them in the United States and even some overseas!

His wife makes all kinds of signs and jewelry as well.

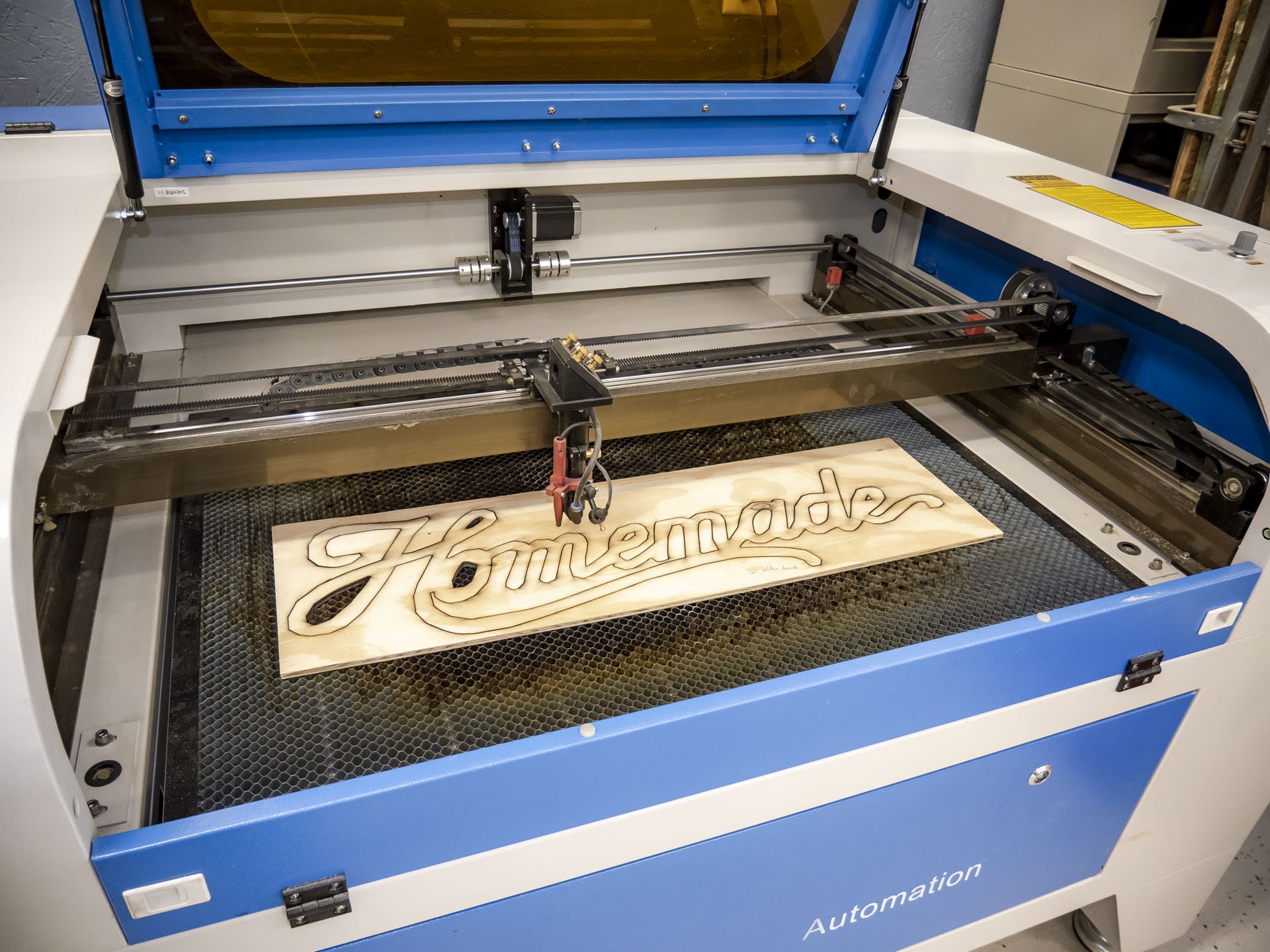

As the demand for larger projects increased, they’ve now fully transitioned to a DWC5100 commercial CNC, plus a 90 Watt Laser - both from Digital Wood Carver.

Here’s a walk through the Bowlby’s CNC success story, told by none other than the man himself.

How it Started

“My wife Krista and I started to make things from wood after I retired from the sheriff's department. We started a small business and started our carving with a Digital Wood Carver DWC2440.

“A friend of mine I went to the FBI National Academy with had one and recommended them. He said the customer service is better than anything I've ever seen in my life and he's absolutely right.”

“I like to carve police badges and I sell them. I've sold some just not only in the United States but outside the United States.

“We started off doing that until someone asked us to carve a 30 inch batch. So we couldn't carve a 30 inch badge based on the size of the machine we had, so we talked about it.

“We got a text kind of a broadcast from Laney, and they had one DWC5100 that they were going to sell before the price increase. We contacted Burl and asked him to hold it for us and drove down to Martinsville.

“Talked to Burl about it and what the differences were, the pluses, the minuses. We reorganized a little bit and they delivered it in August.

“So now we can now not only cut the small badges that we once did but we can cut something as wide as 50 inches and as long as 100.”

The DWC5100 Machine and 90-Watt Laser Quality

“I seldom have any trouble with it.”

“The 220 volt, water-cooled spindle is much quieter than the router was and you can actually stand nearby and have a conversation while the spindle's running. The size of the table obviously was another factor, and just the sheer size and the weight of it and how well it's put together.

“The good thing about it too, different from a router, not only are the feed rates but the speed rates of the router bit itself they're adjustable so you can vary the speed and feed rates which makes up the whole cutting process suit your project.

“The VCarve Software makes it so easy for the average person to use. It takes a lot of the guesswork out of it.

“the laser does a lot of different things than the CNC does because it can do finer detail on smaller things”

“In January we bought a 90-Watt cabinet laser. My wife's wanted one for some time and she started working with it and it's just about running 24/7 ever since!

“Krista's getting ready to cut some leather with our machine. She's also used her laser on canvas bags, cloth bags, cotton bags, acrylic…”

“It's helped us expand our business, and it's helped us meet new people.”

Starting with Zero CNC Experience

“I knew the concept [of CNC] but I knew nothing about programming. I knew nothing about how to make it run. I knew nothing about designing...”

“This whole CNC process is not very straightforward. It's complicated, but it can be learned. I learn a lot from videos, I learn a lot from other people who have experience.

“With Laney's expertise and knowledge, passing that along in little bits so that I could absorb it and be able to retain it. Then I've learned enough that I can do a lot of things.

“You can't take everybody's word as a gospel, you have to kind of make your own decisions based on what you know and the capabilities of the machine. But I have confidence in this machine that it'll do just about anything I want to do”

Why Digital Wood Carver?

“The fact that they're there anytime you call them for anything”

“I've talked to [Laney] enough that I can send him a text message and explain to him the problems I'm having problems with and he'll either send me back an answer or he'll call me within a few minutes.

“The customer service is outstanding. The company itself is outstanding, and I've met several of the guys that work there and they're all good people and they would stop to do anything they can to help you.”

And that’s a wrap!

We are extending our sincerest gratitude to the Bowlby family for sharing their inspiring CNC success story. It is our pleasure to be part of this journey and as always, we hope for nothing but better days ahead for you, your family, and your CNC business!

To learn more about Bowlbywood Creations and their wondrous custom-made products, you can visit their official website and Facebook Page.

Level Up Your Sign Making Business with the SmartBench Large Format CNC!

Add a large-format CNC to your shop for less than $10,000 and cut signs from multiple materials like wood, B-board, corrugated plastic, etc as well as use for plotting or as a vinyl cutter!

Add a large-format CNC to your shop for less than $10,000 and cut signs from multiple materials like wood, B-board, corrugated plastic, etc as well as use for plotting or as a vinyl cutter!

No CNC? You’re Missing Out!

Producing large signage is challenging for any small sign-making business. The lack of space and machinery limits you to smaller project sizes, restricting your ability to support your customers.

This problem can be solved with a large-format CNC router that is easily collapsible and affordable… CNCs are a versatile addition to your sign-making arsenal, multiplying the ways you can provide value for your customers.

When used together with existing resources such as vinyl cutters and printers, a large format CNC allows you to cut out large signs quicker and more efficiently, and provide more value-added services in addition to more basic signage requests.

CNC routers can cut through a wide array of materials like foam core, corrugated foam, plywood, plastics, acrylics, ACM, vinyl and so much more.

Cutting acrylic

So you’ll be able to achieve higher-quality products without the need for extra hands and all-nighters doing it with a table saw and jigsaw or outsourcing!

The CNC Learning Curve

Integrating a CNC router is pretty simple for most sign makers because the production process is very similar to what you’re already used to.

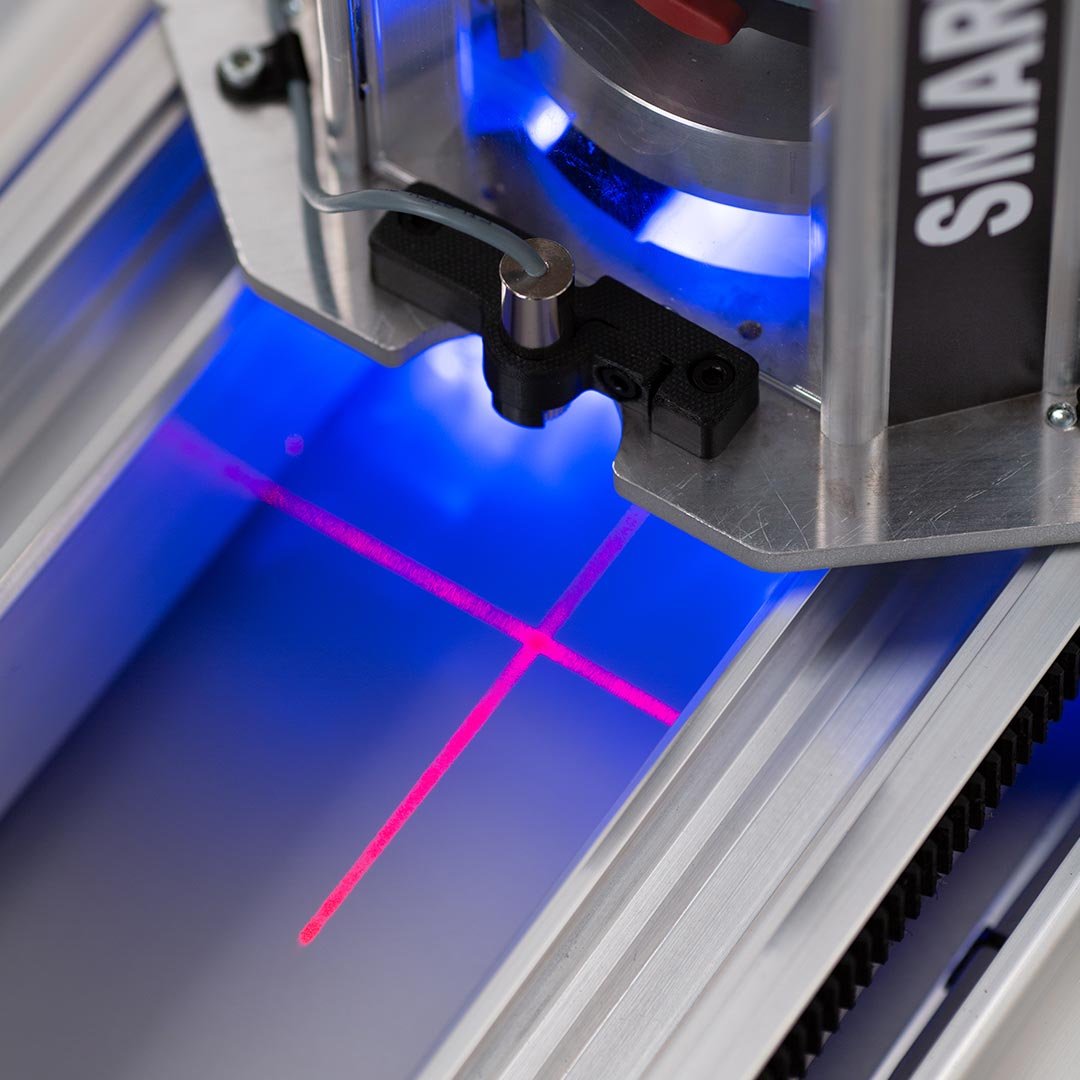

Visual display makes it easier to get projects running

Once you have your 3D or vector-based design, all you need to do is load it onto a USB and plug it into your CNC, and input some basic CNC-specific information (bit size, depth, cutting speed, etc.). Then, you can set up your material on the machine, load the project, and let it run!

SmartBench Precision Pro – The Best CNC Router for Sign Making

Precise cutting of a variety of materials including acrylic, plywood and signboard.

The SmartBench Precision Pro is the perfect sign-making CNC for small businesses that want to dream big for themselves and their clients.

It gives small to medium-sized businesses the extra cutting capacity and flexibility that they need at a reasonably low price.

It quickly runs 2D and 3D designs and has plenty of room for thicker and larger projects – no more limits!

Here’s a quick walkthrough of the SmartBench Precision Pro key features:

High-Quality and Beginner-Friendly

The patented design of the SmartBench Precision Pro speeds up your entire signmaking production with high precision and full edge-to-edge capability for plywood sheets plus touch screen control.

This CNC router boasts an impressive 98” X 49” carving size, allowing you to carve full sheets of plywood and anything similiarly sized.

It has a real-time spindle load display where you can easily monitor your cutting speed and make adjustments on the spot, and its Z-axis has a 6 inches clearance for thicker projects.

Alternatively, you can also use this CNC router as a vinyl cutter or a drawing tool with the CNC stylus.

Although the SmartBench is optimized to run plastics and wood, there is a plethora of materials you can cut with it including:

Acrylic

Woods

Sign Board / Foams

Solid Surface Material

Aluminum / Metal

A.C.M.

Composites

Plastics

Vinyl

MDF

PVC

Copper & Brass

Coroplast

Cardboard

Cork

Dibond

EPS

Fiberglass

The SmartBench also makes a good beginner signmaking CNC with its integrated touchscreen cutting app – ShapeCutter. The ShapeCutter is a powerful tool with a walk-through job wizard that introduces you to the basics of CNC operation. It provides a step-by-step guide on how to complete your first project on the SmartBench, and its beginner-friendly interface allows for easy task set-ups and navigation.

In addition, you get to choose between 10 geometry types and receive prompts on the whole process. For CAD/CAM users, the ShapeCutter is also compatible with 95% of existing software packages you may already have.

Affordable Sign Making CNC Router

One thing that discourages many businesses from getting a CNC is the cost.

A traditional sign making CNC router is expensive. They usually start from $35,000 and an investment this large understandably scares off small sign making businesses. Because of this, smaller businesses have no choice but to limit their products to smaller-sized signage and their customer reach as well.

But with SmartBench, you can now optimize your operations for way less!

The SmartBench Precision Pro is a large CNC for signmaking that costs less than $10,000. With this investment you can already enjoy its highly-efficient features and the entire software package. Spend less, earn more!

Compact Sign Making CNC Router

To top it all off, the SmartBench is a compact signmaking CNC that is portable and boasts a speedy 3-minute assembly!

Perfect for smaller spaces, you can easily keep it in one corner while it runs, and disassemble for storage. Unlike other bulky equipment, you can now make the most out of your space.

Expand your Sign Making Potential with a CNC Router

CNC technology has become more and more accessible to the public. Expensive commercial machines were once the norm, but we’re now seeing more beginner-friendly models that anybody can use.

At Digital Wood Carver, we’re committed to bringing these right to your doorstep. Get a quote now and level up your business with SmartBench.

Father/Son Carving Duo Combines Learning, Creating, and Time Together

A son’s request for pocket money is the spark for a burgeoning father/son woodworking business.

A son’s request for pocket money is the spark for a burgeoning father/son woodworking business!

Recently, someone asked for input on the ROI of a Digital Wood Carver, and out of the many great comments that customers gave, one in particular caught my eye from Tim Maneval who lives in Florida...

“My son (9 years old) and I use it so he can earn a little cash. We make flags and some basic signs. Usually three signs a month pays for my DWC2440.”

Tim is using a DWC2440 CNC together with his son to build things that also can bring in an income. It seemed to me that a Digital Wood Carver could really present a wide range of practical learning opportunities for young people, and I sent Tim an email to see if he could elaborate more.

There’s so much great information in what he sent back to me, I feel like it’s better that you just read what Tim had to say. His story is full of great ideas for involving kids in hands-on activities where they can learn all sorts of practical skills and responsibilities, as well as ideas for those initial sales when you’re just getting started in a new woodworking adventure and would like to be able to justify the investment with some sales! I’ll turn it over to Tim...

---

“When I was young, my dad took me to a friend of his once a week who taught me woodworking. After I went to college, I served in the Army for 8 years. During that time I picked up my wood working again between deployments. I often would lose interest because each time I found a new project, it usually meant I needed to buy another piece of expensive equipment.

Tim in Iraq

“I think that is why the CNC really hit home with me because it is so versatile.”

Tim is now a supervisor for a manufacturing company and his teams program and run machinery, so he’s familiar with how they work.

“At Christmas time, my daughter asked me to help her make "pallet wood Christmas" trees. My kids are 9 year old twins, son and daughter. So I pulled out my equipment and really started searching the internet for CNCs again.

The Pallet Christmas Tree!

“About the same time, my son asked for some money. Being old fashioned, I asked if he would want to earn it. I showed him some flags being made and we talked through making them. So we made a plan to hand make some flags and sell them until we saved some money for a CNC.

“Our first flag was Dremel etched stars. WOW, that took hours and didn't look really professional. The guys that have the patience and talent for that are amazing. Then we made vinyl stars on a Cricut which worked nice but lacked the real woodworking touch.

“Fortunately for us, this is when our local woodworking show was coming to town. So we went to the show and found the DWC team running samples and current owners bending over backwards to help us decide.

“Like most people, I had seen super small Asian models being sold everywhere but were way too small and lacked any software. Looking back, I was really close to a few of the other cheaper brands...

“I am so glad I went with the DWC. My son and I were able to set it up in a matter of hours, follow the YouTube videos of set up, and were cutting right away. I'm not sure my son would have made it through a 2 day install.

“Also looking back, I see a lot of the other machine owners always buying upgrades, aftermarket add-on parts, etc. The DWC worked straight outta setup.

Laney actually had a class on making a flag, we followed the part about making a star, wrote our program on V-Carve and it ran perfect on the first try and we just kept repeating it.

“My son likes these types of projects because we can get them done. When I was young doing hand woodworking, projects would take us months to complete. We can do a few flags in a day or a one-piece flag on the machine can be done in hours.

Obviously, his generation is very digital so he likes to be able to combine his computer skills with a machine. To him, it is like playing a game but it tells the machine to make something.

Being nine years old, sanding and staining helps burn off his energy. Using the tape measure, he is reinforcing the fractions that he is learning in school. We are even working a little on a budget for us.

So our "business" plan was to make a stockpile of flags, take them to our monthly neighborhood market and then to sell on Facebook. Well, we made the first few for family and friends and then decided “Why don't we have all the 9 year olds in our Cub Scout pack make their own flag?”. So we spent 3 Cub Scout meetings and each Cub Scout made a flag with their parents helping some.

“The referrals from family, friends, and cub scouts that got those first flags are more than we can keep up with. The neighborhood market has been cancelled with the COVID-19 issues and we have enough sales that we haven't advertised on Facebook yet. We now have our flags pretty nailed down, so we are looking to try some other products.

“We made some Quarterboard signs following Laney's YouTube video for my daughter’s horseback riding instructor. Same thing, we gave her one and now people are asking for some.

“We are also looking to combine the use of our Cricut with our woodworking. A future step is for us to also learn epoxy resin projects. Many projects are easy to try since VCarve is fairly universal. We can buy a file on Etsy for a few dollars and try it. Much easier than spending hours trying to draw it ourselves.

“I got my son involved by promising him he could earn money. I also let him do the transaction when he gives the flag to the person, he collects the money, and he separates his portion out.

Scouts Project

I got the cub scouts to try it just by showing them a finished project and saying show up on Thursday nights and we will make one. It really helped that their parents came over and watched while 13 kids worked in my garage all at once. They thought the nail gun was the coolest thing ever.

These type of projects with the CNC have really nice quality and they look better finished than the average nail together build project that kids often do in Cub Scouts and etc. This looks like real woodworking. My next upgrade I hope is to add the laser so I can put a logo and etc on the back of our projects. But I had the kids sign with a burn marker and then burned it on. They were really proud of that.

Growing Sales and ROI

So far getting customers has been easy - get a few products in the hands of people and they show friends. I ended up setting up a dedicated email, and I learned how to ship from the UPS store. The referral network is a lot bigger than I expected. We have shipped to NY, PA, North Carolina, Minnesota, Wisconsin, and we live in Florida!

My initial thought was to buy the smaller unit [DWC1824] and that would have done a lot of the flags and projects we have tackled so far, but I'm really glad that we went with the bigger unit [DWC2440], it gives us a lot more options to try with and to set up two projects at a time.

We used our bank for a small personal finance loan. At the current rate that we sell flags, we can pay for the wood, pay my son's work, and pay the loan back with four flags per month. Our flags are fairly cheap for our area, I know people selling similar flags that could pay the monthly payment selling one flag.

Quarterboards sell extremely high in my area. Also corn hole boards sell really high. In general we do two or three flags a week depending on how motivated we are. School at home during COVID19 has made it harder. We are easily making our payment and saving up money for other tools.

Support from Digital Wood Carver

“In general the DWC team has made the project a success. It was a complete kit, no add-ons, upgrades, aftermarket fixes, etc.

“The software does what is really needed. I see owners of other equipment who get poor quality from a good machine due to software issues.

“And then SpindleTV is a bonus. We don't always make the live videos, but we watch them on the channel later. The process has been so easy, that I haven't even used the free training course for new buyers. I don't have any questions to ask. The couple questions I have had, other owners answered before I even needed to reach out to Laney or your team.”

We would like to thank Tim for sharing his experiences and perspectives with us. And also we want to wish him continued success with this new family woodworking business!

Contact information for Tim:

Email: mainstreet727@gmail.com

Instagram: https://www.instagram.com/mainstreet727/

Facebook: https://www.facebook.com/MainStreetInnovationsLLC/

Gary Clink Makes FUN Carvings!

Check out Gary Clink’s assortment of fun signs and playful characters he made with his DWC2440 CNC Wood Carver!

Gary’s Story

Gary Clink wasn’t looking for a CNC Carver but once discovered at a show, he got a DWC2440 Workshop CNC Router in 2015 and now loves it. The highlight for him is the customer service from Digital Wood Carver and the construction quality of his CNC, which he rates as “excellent”. Whenever he has an issue, he says his “questions are always resolved.”

He uses his carver to make decorative boxes, custom signs, and unique coasters.

Razorback Clock from Ragan Hilmer

Check out Ragan Hilmer’s Razorback clock he made with his DWC2440 CNC Carver for his shop office!

Ron’s Story

Ragan Hilmer uses a DWC2440 Standard Digital Wood Carver to make custom wooden clocks. He likes clocks and how they work and recently sent pictures of a couple of his finished projects.

One of his completed clocks is the Wooden Razorback Clock created for his shop office. It is made with pine and the dimensions are 22.75” tall x 32” long 1 1/2” thick.

He said the projects were relatively easy, but the finished products certainly turned out great!

Check out Ragan’s company on the RTH Hand Crafted Signs & More Facebook page to see more of his work!

Ragan’s DWC2440 in his workshop.

Project Collection by Ron Galilei

See a collection of projects that Ron Galilei from Monessen, Pennsylvania has made using his DWC2440 Workshop CNC.

Craftsman

Ron Galilei - Monessen, PA

Machine

Ron’s Story

“I had a problem at the very beginning, but Burl resolved the issue immediately. To resolve the problem that I was having with my DWC, Burl had made arrangements with me to personally deliver a brand new DWC to my home. So I'm not talking just around the corner, Burl drove a new machine from Indiana to my home in Monessen, PA (south of Pittsburgh). That was about a 6 to 7 hour trip, one way. He arrived, we unloaded the DWC, and he went through the entire setup process with the new machine.

“So, if anyone is considering a DWC, there is no doubt in my mind that there would not be any other people out there who provide the service and support that you will get from Burl and Laney.

“Thank you Burl and Laney for everything you do for all of your customers.”

Carved Panels for Custom Bar

See how Westley Campbell from Pennsylvania used his DWC5100 commercial CNC to produce carved panels that were used in a home bar built by a customer.

Craftsman

Westley Campbell - Campbell Signs and Designs

Machine

Material

Rustic maple with black walnut trim

Project Info

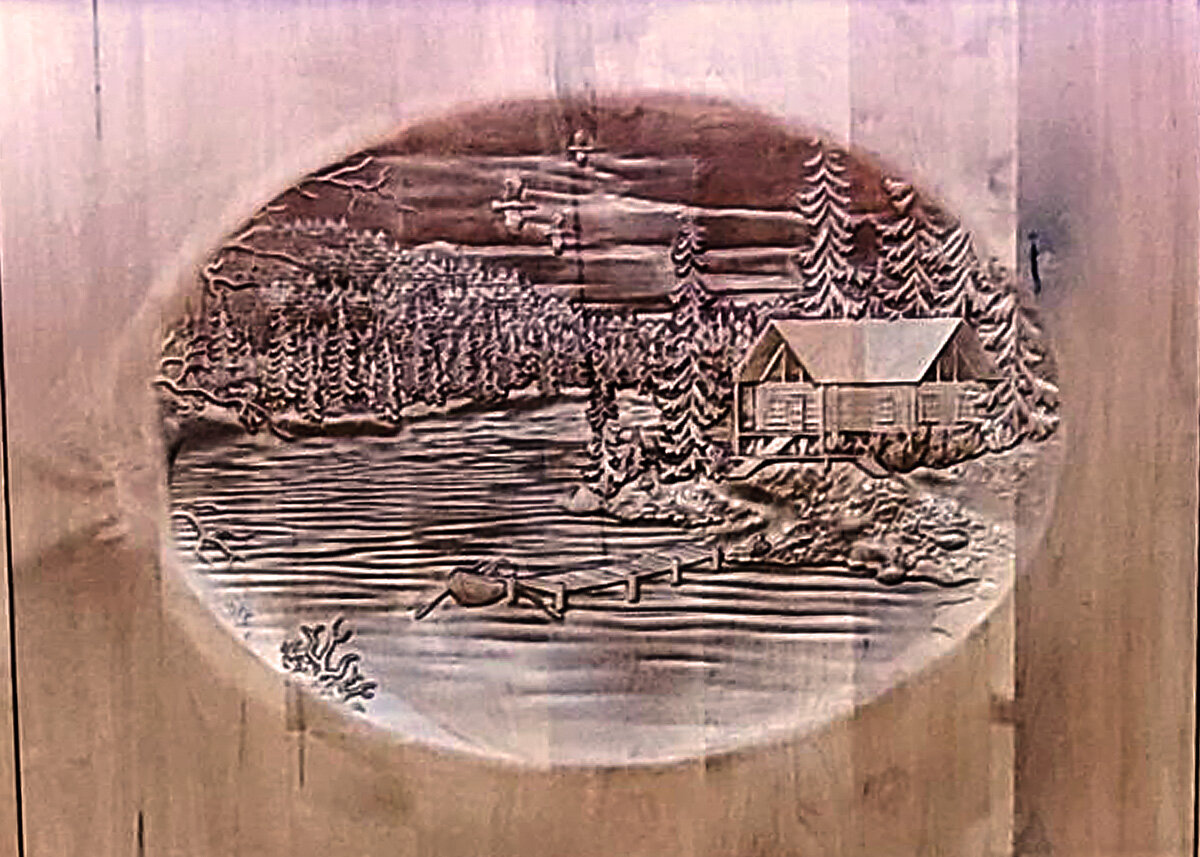

Westley Campbell installed a DWC5100 commercial CNC in 2018, and recently shared pictures of one of his notable projects - carved panels that were used in a bar construction made by a homeowner.

The DWC5100 has a working area of 51.2" x 98.4" to accommodate full sheets of plywood.

The cabin scene took 26 hours at 45 in/min single pass. All the panels were run on the same .125 tapered ball mill.

“I can't take any credit on the bar construction,” Westley says. “The homeowner was pretty handy himself. I just supplied some design work and carvings.”

Westley recommends that people interested in getting a CNC shouldn’t just be thinking about the carving they can use the CNC for, but for all the other kinds of things they can produce as well.

“I use both of my DWC units for cutting and mill work as well,” Westley says. “A lot of my business comes from Victorian reproduction items such as profiled flat panel balusters.”

Westley’s DWC5100