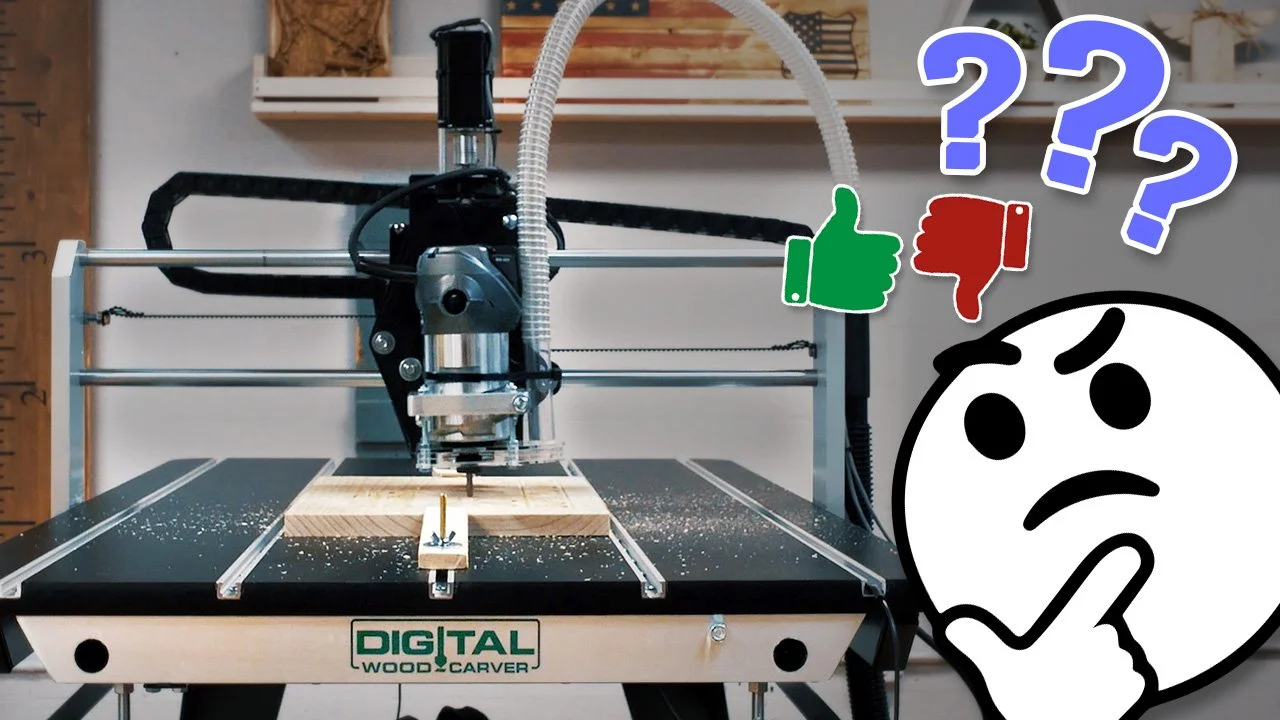

New to CNC? Start with the DWC1824 Mini!

New to the world of CNC carving and wondering where to start? The DWC1824 is the CNC for you! The DWC1824 Mini Carver allows you to start with a high quality CNC that is not only highly capable and well built, but is also affordable and conducive to learning. It is easy to operate, compact, and equipped with everything you need. No prior experience in CNC is required to begin!

New to the world of CNC carving and wondering where to start? Then the DWC1824 CNC router is the CNC for you!

As a beginner, we recommend that you work with smaller projects first and develop your skills and knowledge through practice.

The DWC1824 Mini Carver allows you to start with a high quality CNC that is not only highly capable and well built, but is also affordable and conducive to learning. It is easy to operate, compact, and equipped with everything you need. No prior experience in CNC is required to begin!

Why the DWC1824?

If you’re a beginner looking for an all-around CNC router that can grow with you and unlock your creative potential, then the DWC1824 Mini Carver is your best bet.

Unlike other entry-level CNC routers that are foreign made as a kit and have to be fully assembled before use, the DWC1824 is made in the US, and ships to you pre-assembled and plug-and-play ready - router, design software, controller software and even bits are included!

It has a compact footprint for workshops that don’t have a lot of extra space. Plus, you can add accessories like a laser, 4th Axis attachment and more to fit your needs, extending your capabilities even further

This makes it perfect for people with limited spaces and people who want to get to work immediately. What you see is what you get at a reasonable price for a US-made CNC that comes with extensive after-sale support.

Here is a step-by-step guide on how to begin your CNC journey with the DWC1824.

Learn CNC with Us

Before anything else, you need to have at least an idea on what you’re getting yourself into. And great news is that Digital Wood Carving offers massive support for beginners. No need to be too tech savvy, just have the motivation to learn and you’re good to go!

Initial Orientation and Training

Upon purchase, your CNC comes with start up videos that show you EXACTLY how to set up your CNC, install the software, and design and carve your first project. So even if you’re brand new to CNC, all you have to do is follow along!

Plus, to answer more questions and make sure you’re starting strong, every new customer gets a two-hour long one-on-one orientation and training right off the bat with our experienced staff!

This training will teach you how to use both the DWC1824 software and machine and help you start on the right track. An interactive manual is also integrated into the software that walks you through all of its features.

Interactive LIVE Design Tutorials on YouTube

You will also gain access to tons of tutorial videos for your reference. There are videos on how to install your software, how to use certain accessories, how to design your first project, etc.

Aside from tutorial videos, we conduct LIVE classes on Youtube (Spindle TV). Every Tuesday night, our pro CNC specialist hosts the classes, which are interactive. We will address any question you have real-time!

User Support Group

Digital Wood Carver also established a private support group on Facebook called the Digital Wood Carvers Owners Group. Here, other experienced owners help new owners get started, answer questions, share experiences and project files, and more.

This community exposure not only expands your CNC knowledge but also encourages you to try out new things and make friends with other CNC operators.

Start Simple

With some research and training under your belt, it’s time to put all that into practice. The DWC1824 uses the Vectric VCarve Desktop Design Software to design projects.

If you’re concerned that the software will be too technical for you, don’t worry, it’s the industry-standard largely because of how powerful and intuitive it is to use.

Plus, you’ll be able to follow along for your first projects with our startup videos and training tutorials (mentioned above) and you can learn more about it during the training and from the video resources you can access.

Start building up your skill by opting for the most basic projects to maximize your chances of success. For example, you can carve out simple texts and patterns on nameplates, jewelry box covers, etc.

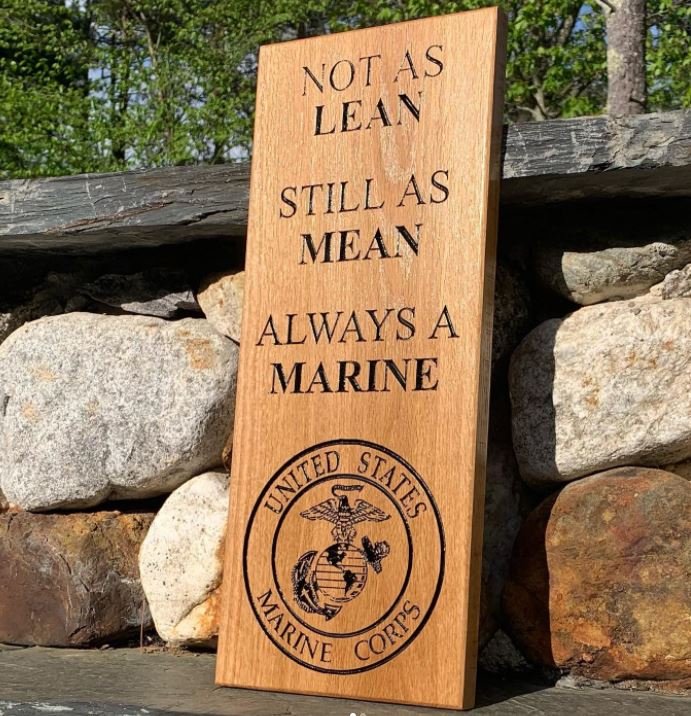

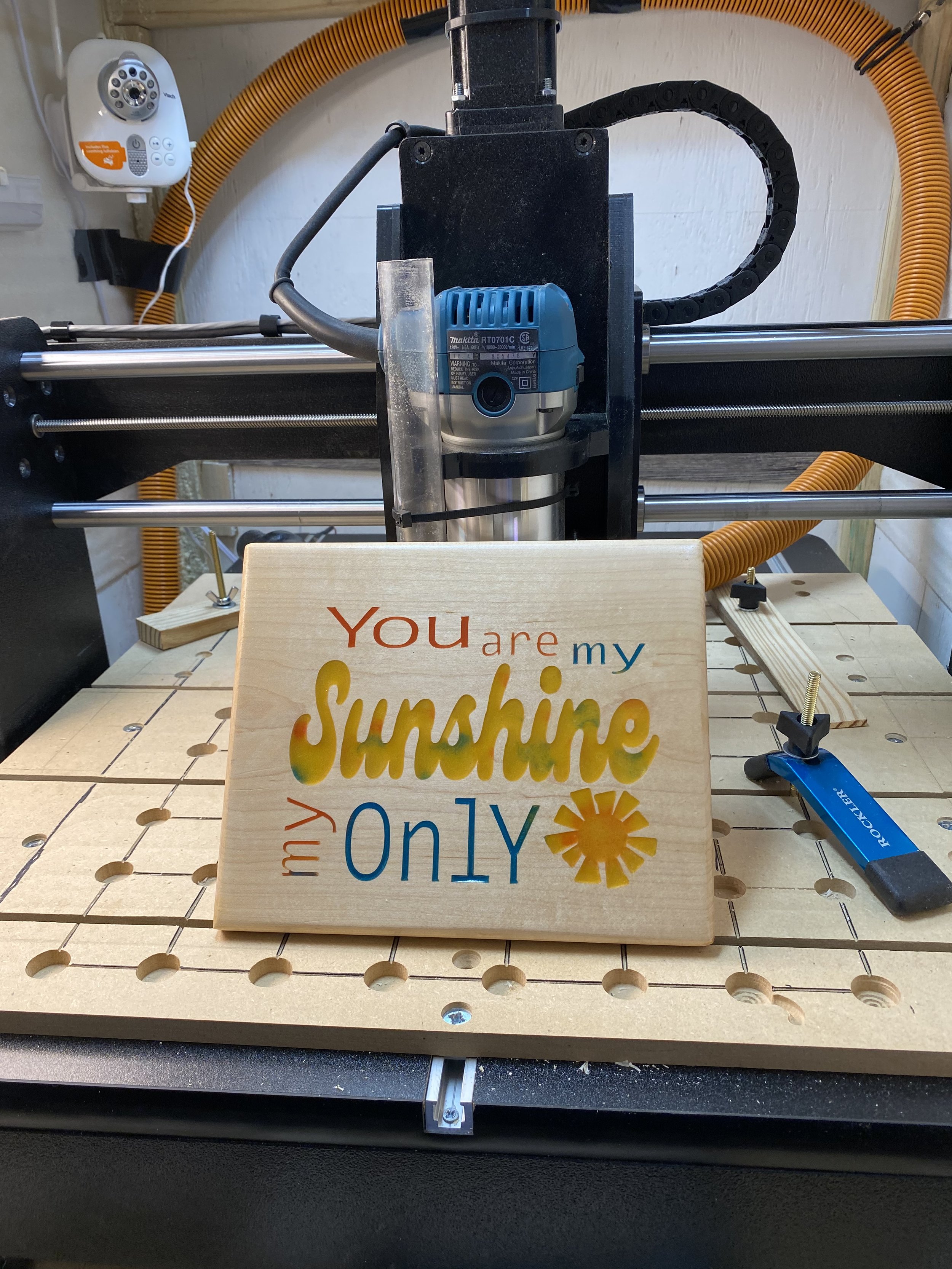

For more ideas, here are some beginner-friendly designs previously made by our customers:

Starting with something simple gives you a straightforward idea on how the finished product should look like. As soon as you get the hang of it, you can switch up to more challenging patterns and images.

Here are the types of files you can import on the DWC1824 design software:

Vector Files

dxf

.dwg

.eps

.ai

.pdf

.svg

.skp

Image Files

Bitmap

Pixel

JPEG

PNG

GIF

TIFF

3D Models

STL

OBJ

PRJ

3DS.X

Get Creative

Once you get the hang of creating straightforward designs, you can begin to experiment with more advanced carves, creative techniques and try out designs on different kinds of materials.

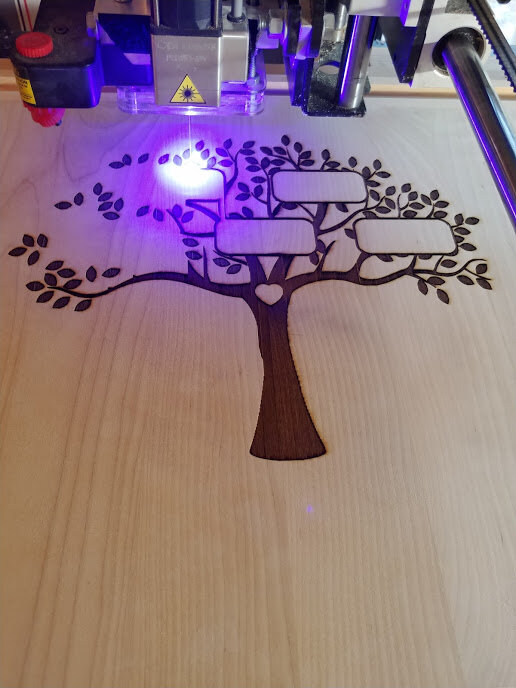

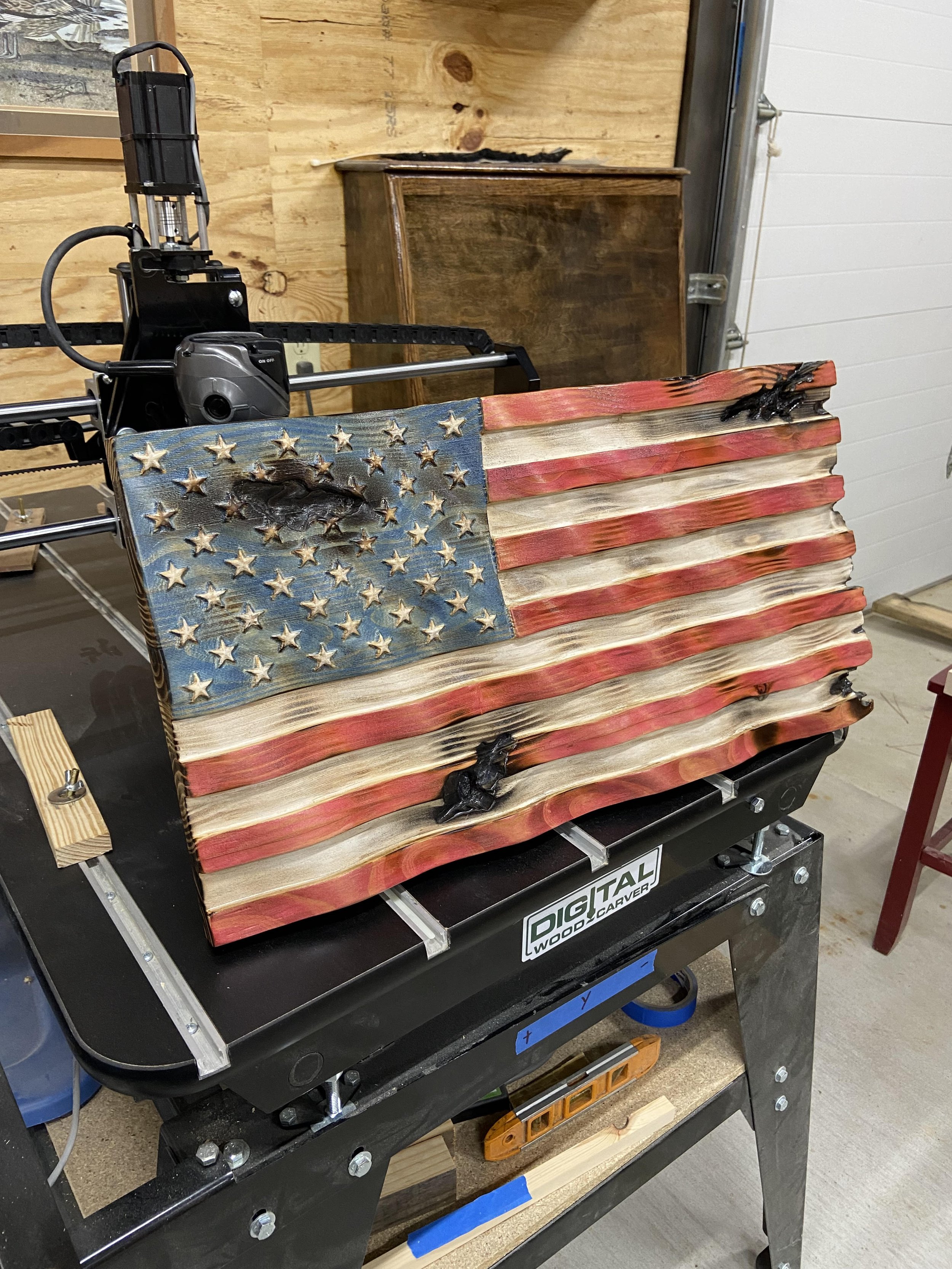

Check out some of these advances projects other DWC1824 owners have made:

Plus, you can extend the capabilities of the CNC router with different accessories:

Six-watt Laser (for laser engraving)

4th Axis for rotary carving

The Sky’s the Limit!

Consistency is the key to mastery. After finishing one project, then it’s time to plan another and the cycle continues until you get comfortable. It’s also good that you challenge yourself with complex designs every now and then. Not only can this help you develop your skills in woodcrafting, but the mistakes you make will help you grow.

Just like Burl Tichenor, owner of Digital Wood Carver, says - “Nobody that has the desire, cannot learn to do it. There is no shame in being a beginner. In fact, you should be proud as this simply means that you're opening doors to a new journey.” So if you’re thinking of learning CNC and further honing your woodworking skills, then go for it! Support and help is always here for you.

Discover more about the DWC1824 Mini Carver and other available CNCs.

Absolutely Awesome Things You Can Do With A CNC Router

Discover the endless possibilities of what you can make with a CNC router in your workshop!

From 3D wood carvings to carved plastics to laser engravings, check out the different types of projects that a CNC router can help you produce.

Expand Your Capabilities with a CNC Router

With advances in technology and software, modern workshop CNC routers enable even novice woodworkers to produce all sorts of projects - wood carvings, carved plastics, cutting boards, and even soft metal projects, can be made using just one tool.

One CNC can replace many tools that were traditionally necessary in most workshops - saving space while making things much easier when doing repetitive milling tasks.

The possibilities are endless when it comes to utilizing the power of CNC routers. Let’s explore the different types of amazing projects that a CNC router can help you with. But this is just the beginning… There's no limit as long as you're creative and imaginative!

Carve Unique Projects from Wood

Signs, plaques, games, cutting boards, and flags.

A CNC is a great way to turn your wood projects into works of art. You can create unique signs and plaques for any occasion. Cutting boards are a really trendy right now and make for a great personalized gift! As well, a CNC can help you to cut out materials to make games or other items that need precise and unique shapes.

The best part of using a CNC machine to carve your projects from wood Is that unlike hand-carving, which can take hours and produce inconsistent results due to human error or lack of skill, CNCs provide consistent results every time.

Make Money & Special Gifts

With a CNC in the workshop, you can make nice gifts for family members or friends who love homemade items. The possibilities are endless when you're armed with this kind of technology in your arsenal - all that's left is for you to determine what will happen next.

Many CNC owners are able to build part time and even full time income by starting out this way and then beginning to offer their services through local word of mouth and by selling online.

Cut out 2D Designs from Cardboard, Plywood, Foam and more...

CNC routers are often used for to precisely cut out intricate shapes from cardboard, foam, and plywood.

With this helpful tool, you could make all your DIY projects much easier than they seemed before because now there's no need to spend hours trying to trace your 2D designs.

Carve & Engrave plastics to make one-of-a-kind gifts like LED lamps

Some of the more creative projects to make with your CNC router are one-of-a-kind LED lamps for gifts or for sale. By engraving on the surface of plastics, and pairing it with a simple LED light fixture, you can easily and quickly offer custom items that everyone will love.

With LED lamps becoming increasingly popular and affordable, you can now have your own personalized lighting fixtures in your workshop as well!

A CNC router allows for detailed carving or sculpting of plastics with speed and precision, making it feasible for artists to offer unique products that are not mass produced.

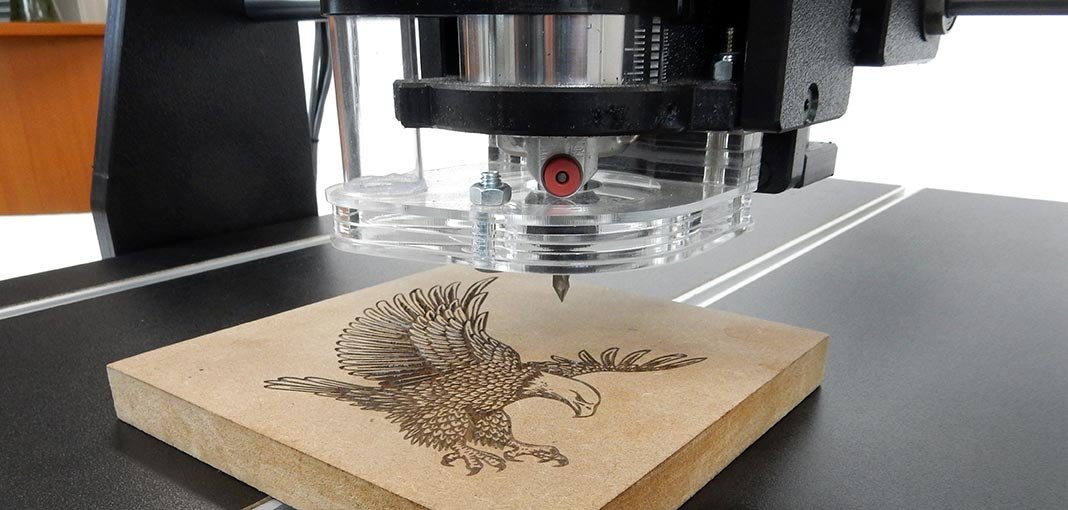

Laser Engravings

When you need a custom laser engraving on wood for a logo, motto, anything else, a CNC equipped with a laser is a perfect way to make it happen.

With the optional laser addon, your CNC router can create detailed engravings with great accuracy and speed, enhancing your projects even further.

4 Fun DIY Carving Projects Made Easy with a CNC Router

Want to know what you can make with a CNC Router?

Here are four kinds of CNC projects that you can make!

Getting yourself a CNC Router can spice up your DIY projects massively. A CNC allows you to accurately cut, carve, etch and engrave different materials such as wood, foam, plastic, and even some soft metals to create unique finished products.

With it, even hobbyist woodworkers can try out advanced carving techniques and businesses can mass-produce customized products quickly without spending a fortune. In other words, it opens up a whole new world of possibilities for workshops both small and large.

As a heads up, here is a quick video compilation of some of the amazing DIY projects our customers have created with their very own CNC Router.

We’ve compiled four impressive kinds of projects that you can make with a CNC Router:

Unique Home and Office Items

Nothing is better than items that have a good balance of both form and function. With a CNC Router, you can transform common home and office items into something truly special for yourself and for others.

I mean, why should you buy something that everyone else has if you can create your own ?

Transforming common items into something more unique is a great way to earn extra income. Small business owners don’t have to be afraid of competing with big box stores, because many consumers are becoming increasingly conscious of where they’re buying, (especially millennials) and many prefer to buy one-of-a-kind items to support local business.

Best-Selling Customized Items

Personalized Cutting Boards

Pencil Holders

Coasters

Desk Organizers

Make Unforgettable Gifts For Loved Ones

Gifts that are created especially for you hold great, if not, the most value. So if you’re someone with a gift-giving love language, then you might be thrilled to explore possibilities with a CNC Router.

You get the luxury of transforming ideas into reality easily regardless if you’re a novice or an expert in woodworking. Emblazen your loved one’s name on their favorite items, or even create toys and coasters shaped like their favorite animal!

Awesome Gift Ideas:

Custom Board games

Puzzles

Name Plaques

Jewelry

Accessories

Design 2D Decor to Spice Up Your Space

The value of an aesthetically pleasing home or office space cannot be underestimated.

So, another project that might pique your interest is designing 2D decor to beautify your space. With a CNC router, you can cut up 2D ornaments out of various materials like wood, foam, plastic and other materials to adorn your wall..

Personalized 2D Decoration Ideas:

Tree Ornaments

Rustic Wood Signs

Monogramed signs

Electrical Outlet Covers

Custom Laser Engravings

Have items that remind you of a special date or person? Engrave it!

With your own CNC router in your workshop outfitted with a laser, you can easily bring meaning to simple objects by engraving names, dates, images and inspiring words on their surfaces.

Whether you’re a hobbyist or a professional, there is always a CNC router that best suits you and your needs.

Don’t be afraid to venture out! Everyone starts as a beginner, and there will always be a chance to learn and improve.

Learn more about the different types of CNC routers and their features by visiting us at Digital Wood Carver.

Honest Opinions: How does DWC Compare to Other CNCs?

Unedited replies from DWC customers to someone comparing CNCs.

From time to time, we give temporary access to our private DWC Facebook Owners Group (now over 1,000 members!) to people who want to ask questions before they commit to buying a CNC.

Anyone can make flashy videos and have a good looking website, but feedback from real customers is where you learn the truth about a company, its product and customer support!

Original Question

Recently, someone asked the following questions in the group…

“I am a new wood lighting manufacturer that plans to make a lot of my components from a CNC. The pieces are pretty small, so a smaller footprint CNC should be sufficient for me. I still have some questions perhaps some of you could help me with:

-Has anyone used a Shark HD5 series and can compare/contrast with the DWG?

-How has your machine held up to regularly cutting out 2” pieces of walnut for example?

-Has anyone used the 4th axis spindle?

-What do you think of the software?

-Any concerns I should be aware of?

”

Replies

The following questions and answers from customers are completely unedited and we didn’t leave any comments out. We just copied and pasted the text from the original thread.

“I looked at the shark. I ended up with the DWC. It is not just machine compared to machine. The customer service that we get is not limited by time. It is priceless.

While you can probably find good machines, you cannot find the customer service anywhere that even comes close to what DWC offers. Anything else for me would end up a boat anchor.

If you do a lot of cutting you might consider the spindle instead of the router. Almost everybody will tell you the same thing.

DWC is the only way to go.”

“I cut walnut, maple, cherry, ash, oak, mahogany, pine, cedar, alder and probably some I forgot all the time. Most all delicate pieces and multiples.

The machine handles them fine and I have had mine for about 5 years with very little maintenance. It averages 40+ hours a week.

The software is great and easy to figure out. I know you said a small foot print would be fine but if your running several pieces it is great to have a big footprint and do them all at once.

”

“I’ve had my DWC2440 since Oct and Laney has been terrific with his training and readily available for any and all questions. DWC is the only way to fly.”

“When I call my customer service “Laney” and he’s at the gym and still takes my call and walks me through my mistakes not the machines I really am impressed.

Man’s pumping iron and raising spirits at the same time!!!”

“Walnut is what I like carving the most on my 2440 this company is the best you will never find a better support with any other company I have had my machine since 2017 and they have been there for me and still are”

The DWC1824 ‘MINI’ Carver at work.

“This is just an observation and suggestions. I have the DWC 2440 and can’t say enough good things about it. While the DWC1824 may be closer in size to the HD5, it’s always been said to go with a bigger unit first, as you will always want bigger soon.

If you are cutting a lot of pieces, the 2440 will save time in being able to do more parts at a time.

From an observation standpoint the DWC appears to be a sturdier machine. It is also priced slightly lower than the HD5, and comes with the router - that you will have to buy separately with the HD5.

They both claim to come complete (which having the DWC come complete was a game changer for me, as I am very mechanically challenged, and would not be able to put together a bucket of bolts other brands come as).

One of the big things to consider is the machine reliability, software used, and most important the customer service. I’m not familiar with the controller software for the HD5, but the planet CNC controller software with the DWC models has capabilities I’ve heard others don’t (like being able to start again from same spot in case of power outage/surge - although Laney had to help me with that).

There have been other times he’s had to help with something in that software. If you are not familiar with vetric or controller software, that could be worth it’s weight in gold, as it has been for me. Laney team viewed in to both my laptop and desktop computer and set up the Vetric and controller software. He has team viewed many times to show me exactly how to do something.

24 hours a day 6 days a week. 2 hour one on one session to get you going. 2 hour training classes on Tuesday evenings, plus the owners only page on FB for even more help. All lifetime free for owners. I doubt you will find that level of customer service anywhere else.”

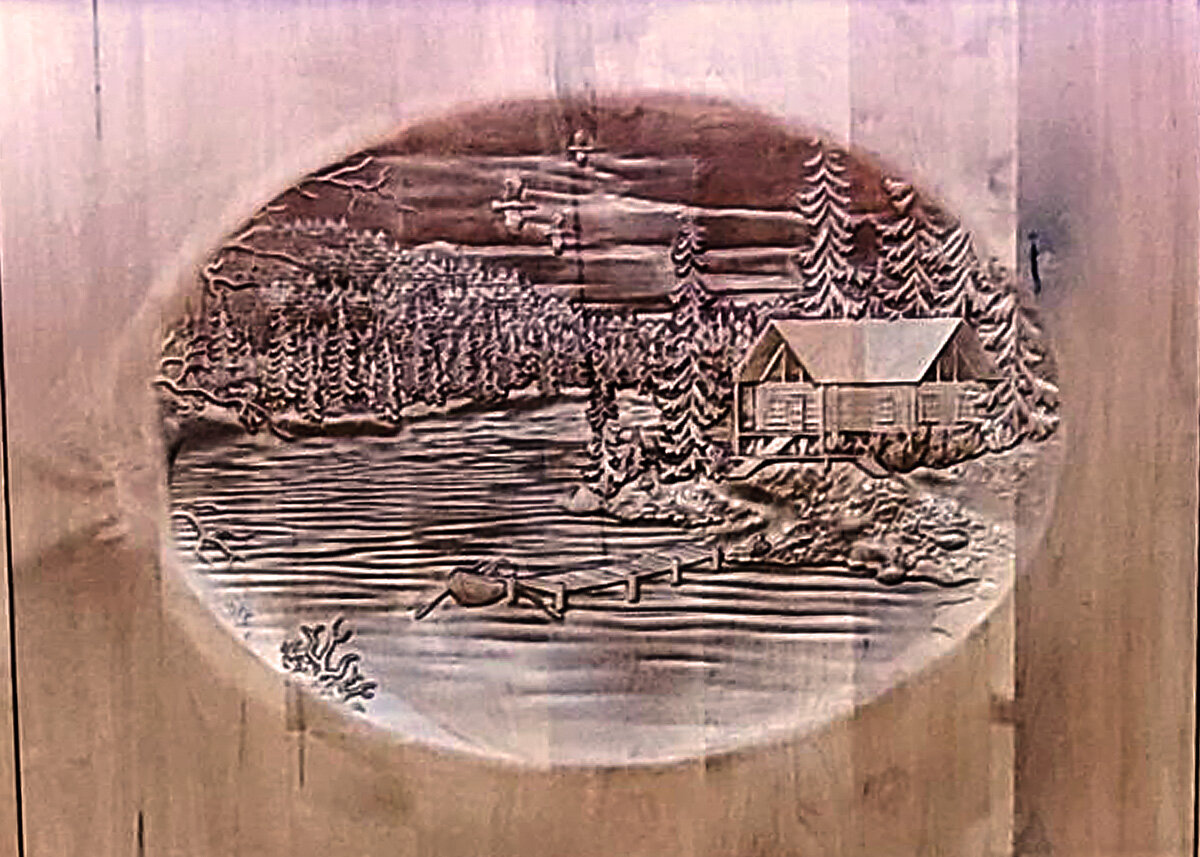

Project made with the DWC2440. Watch the video timelapse.

“I’ll echo what everyone else has said. You won’t find better customer service. I’ve had my 2440 over 5 years, It is my 3rd CNC and easily the best that I have owned.

I did have to replace one belt a few years ago.

To cut 2” thick Walnut, you will probably want to raise your gantry with a kit that they sell. It raises it 2” and the cost is minimal.

I use Vectric V-Carve Pro and it does everything I need. I think that it will easily fill your needs and then some. Good luck with your business.”

“I’ve had mine machine for around 4 years now. bought it used. from my wifes boss.

Had some issues with it. while loading it, i rolled it over the cable from the pendant to the gecko box. after a quick call to Laney and then to Burl. Burl told me to mail him the pendant and a new cable i got off amazon. he fixed it up and shipped it back (i paid shipping both ways) for free.

I’ve been a salesman, and what matters most is the services you get after the sale. Not knocking on Shark cauz i don’t know their products and service.

I know DWC....I know you will be 100% satisfied with the training you will get with your purchase, as well as the ongoing training Laney does frequently. If you decide on DWC...you will not regret your decision! come join the family man!”

Response from Original Poster:

“I want to thank you all for all the great feedback! I think it’s not just the machine and the great customer service, but also the community that makes the DWC a great product.

I also want to especially thank Lee C., he has invited me over to his shop to see his DWC in action and is getting one of my files ready to be cut.

I’m looking forward to getting started”

Got Questions?

Thanks to all our customers who keep us in business and allow us to serve more customers year after year.

If you’re seriously considering buying a CNC router, let us know!

Father/Son Carving Duo Combines Learning, Creating, and Time Together

A son’s request for pocket money is the spark for a burgeoning father/son woodworking business.

A son’s request for pocket money is the spark for a burgeoning father/son woodworking business!

Recently, someone asked for input on the ROI of a Digital Wood Carver, and out of the many great comments that customers gave, one in particular caught my eye from Tim Maneval who lives in Florida...

“My son (9 years old) and I use it so he can earn a little cash. We make flags and some basic signs. Usually three signs a month pays for my DWC2440.”

Tim is using a DWC2440 CNC together with his son to build things that also can bring in an income. It seemed to me that a Digital Wood Carver could really present a wide range of practical learning opportunities for young people, and I sent Tim an email to see if he could elaborate more.

There’s so much great information in what he sent back to me, I feel like it’s better that you just read what Tim had to say. His story is full of great ideas for involving kids in hands-on activities where they can learn all sorts of practical skills and responsibilities, as well as ideas for those initial sales when you’re just getting started in a new woodworking adventure and would like to be able to justify the investment with some sales! I’ll turn it over to Tim...

---

“When I was young, my dad took me to a friend of his once a week who taught me woodworking. After I went to college, I served in the Army for 8 years. During that time I picked up my wood working again between deployments. I often would lose interest because each time I found a new project, it usually meant I needed to buy another piece of expensive equipment.

Tim in Iraq

“I think that is why the CNC really hit home with me because it is so versatile.”

Tim is now a supervisor for a manufacturing company and his teams program and run machinery, so he’s familiar with how they work.

“At Christmas time, my daughter asked me to help her make "pallet wood Christmas" trees. My kids are 9 year old twins, son and daughter. So I pulled out my equipment and really started searching the internet for CNCs again.

The Pallet Christmas Tree!

“About the same time, my son asked for some money. Being old fashioned, I asked if he would want to earn it. I showed him some flags being made and we talked through making them. So we made a plan to hand make some flags and sell them until we saved some money for a CNC.

“Our first flag was Dremel etched stars. WOW, that took hours and didn't look really professional. The guys that have the patience and talent for that are amazing. Then we made vinyl stars on a Cricut which worked nice but lacked the real woodworking touch.

“Fortunately for us, this is when our local woodworking show was coming to town. So we went to the show and found the DWC team running samples and current owners bending over backwards to help us decide.

“Like most people, I had seen super small Asian models being sold everywhere but were way too small and lacked any software. Looking back, I was really close to a few of the other cheaper brands...

“I am so glad I went with the DWC. My son and I were able to set it up in a matter of hours, follow the YouTube videos of set up, and were cutting right away. I'm not sure my son would have made it through a 2 day install.

“Also looking back, I see a lot of the other machine owners always buying upgrades, aftermarket add-on parts, etc. The DWC worked straight outta setup.

Laney actually had a class on making a flag, we followed the part about making a star, wrote our program on V-Carve and it ran perfect on the first try and we just kept repeating it.

“My son likes these types of projects because we can get them done. When I was young doing hand woodworking, projects would take us months to complete. We can do a few flags in a day or a one-piece flag on the machine can be done in hours.

Obviously, his generation is very digital so he likes to be able to combine his computer skills with a machine. To him, it is like playing a game but it tells the machine to make something.

Being nine years old, sanding and staining helps burn off his energy. Using the tape measure, he is reinforcing the fractions that he is learning in school. We are even working a little on a budget for us.

So our "business" plan was to make a stockpile of flags, take them to our monthly neighborhood market and then to sell on Facebook. Well, we made the first few for family and friends and then decided “Why don't we have all the 9 year olds in our Cub Scout pack make their own flag?”. So we spent 3 Cub Scout meetings and each Cub Scout made a flag with their parents helping some.

“The referrals from family, friends, and cub scouts that got those first flags are more than we can keep up with. The neighborhood market has been cancelled with the COVID-19 issues and we have enough sales that we haven't advertised on Facebook yet. We now have our flags pretty nailed down, so we are looking to try some other products.

“We made some Quarterboard signs following Laney's YouTube video for my daughter’s horseback riding instructor. Same thing, we gave her one and now people are asking for some.

“We are also looking to combine the use of our Cricut with our woodworking. A future step is for us to also learn epoxy resin projects. Many projects are easy to try since VCarve is fairly universal. We can buy a file on Etsy for a few dollars and try it. Much easier than spending hours trying to draw it ourselves.

“I got my son involved by promising him he could earn money. I also let him do the transaction when he gives the flag to the person, he collects the money, and he separates his portion out.

Scouts Project

I got the cub scouts to try it just by showing them a finished project and saying show up on Thursday nights and we will make one. It really helped that their parents came over and watched while 13 kids worked in my garage all at once. They thought the nail gun was the coolest thing ever.

These type of projects with the CNC have really nice quality and they look better finished than the average nail together build project that kids often do in Cub Scouts and etc. This looks like real woodworking. My next upgrade I hope is to add the laser so I can put a logo and etc on the back of our projects. But I had the kids sign with a burn marker and then burned it on. They were really proud of that.

Growing Sales and ROI

So far getting customers has been easy - get a few products in the hands of people and they show friends. I ended up setting up a dedicated email, and I learned how to ship from the UPS store. The referral network is a lot bigger than I expected. We have shipped to NY, PA, North Carolina, Minnesota, Wisconsin, and we live in Florida!

My initial thought was to buy the smaller unit [DWC1824] and that would have done a lot of the flags and projects we have tackled so far, but I'm really glad that we went with the bigger unit [DWC2440], it gives us a lot more options to try with and to set up two projects at a time.

We used our bank for a small personal finance loan. At the current rate that we sell flags, we can pay for the wood, pay my son's work, and pay the loan back with four flags per month. Our flags are fairly cheap for our area, I know people selling similar flags that could pay the monthly payment selling one flag.

Quarterboards sell extremely high in my area. Also corn hole boards sell really high. In general we do two or three flags a week depending on how motivated we are. School at home during COVID19 has made it harder. We are easily making our payment and saving up money for other tools.

Support from Digital Wood Carver

“In general the DWC team has made the project a success. It was a complete kit, no add-ons, upgrades, aftermarket fixes, etc.

“The software does what is really needed. I see owners of other equipment who get poor quality from a good machine due to software issues.

“And then SpindleTV is a bonus. We don't always make the live videos, but we watch them on the channel later. The process has been so easy, that I haven't even used the free training course for new buyers. I don't have any questions to ask. The couple questions I have had, other owners answered before I even needed to reach out to Laney or your team.”

We would like to thank Tim for sharing his experiences and perspectives with us. And also we want to wish him continued success with this new family woodworking business!

Contact information for Tim:

Email: mainstreet727@gmail.com

Instagram: https://www.instagram.com/mainstreet727/

Facebook: https://www.facebook.com/MainStreetInnovationsLLC/

Gary Clink Makes FUN Carvings!

Check out Gary Clink’s assortment of fun signs and playful characters he made with his DWC2440 CNC Wood Carver!

Gary’s Story

Gary Clink wasn’t looking for a CNC Carver but once discovered at a show, he got a DWC2440 Workshop CNC Router in 2015 and now loves it. The highlight for him is the customer service from Digital Wood Carver and the construction quality of his CNC, which he rates as “excellent”. Whenever he has an issue, he says his “questions are always resolved.”

He uses his carver to make decorative boxes, custom signs, and unique coasters.

Razorback Clock from Ragan Hilmer

Check out Ragan Hilmer’s Razorback clock he made with his DWC2440 CNC Carver for his shop office!

Ron’s Story

Ragan Hilmer uses a DWC2440 Standard Digital Wood Carver to make custom wooden clocks. He likes clocks and how they work and recently sent pictures of a couple of his finished projects.

One of his completed clocks is the Wooden Razorback Clock created for his shop office. It is made with pine and the dimensions are 22.75” tall x 32” long 1 1/2” thick.

He said the projects were relatively easy, but the finished products certainly turned out great!

Check out Ragan’s company on the RTH Hand Crafted Signs & More Facebook page to see more of his work!

Ragan’s DWC2440 in his workshop.

Project Collection by Ron Galilei

See a collection of projects that Ron Galilei from Monessen, Pennsylvania has made using his DWC2440 Workshop CNC.

Craftsman

Ron Galilei - Monessen, PA

Machine

Ron’s Story

“I had a problem at the very beginning, but Burl resolved the issue immediately. To resolve the problem that I was having with my DWC, Burl had made arrangements with me to personally deliver a brand new DWC to my home. So I'm not talking just around the corner, Burl drove a new machine from Indiana to my home in Monessen, PA (south of Pittsburgh). That was about a 6 to 7 hour trip, one way. He arrived, we unloaded the DWC, and he went through the entire setup process with the new machine.

“So, if anyone is considering a DWC, there is no doubt in my mind that there would not be any other people out there who provide the service and support that you will get from Burl and Laney.

“Thank you Burl and Laney for everything you do for all of your customers.”

Carved Panels for Custom Bar

See how Westley Campbell from Pennsylvania used his DWC5100 commercial CNC to produce carved panels that were used in a home bar built by a customer.

Craftsman

Westley Campbell - Campbell Signs and Designs

Machine

Material

Rustic maple with black walnut trim

Project Info

Westley Campbell installed a DWC5100 commercial CNC in 2018, and recently shared pictures of one of his notable projects - carved panels that were used in a bar construction made by a homeowner.

The DWC5100 has a working area of 51.2" x 98.4" to accommodate full sheets of plywood.

The cabin scene took 26 hours at 45 in/min single pass. All the panels were run on the same .125 tapered ball mill.

“I can't take any credit on the bar construction,” Westley says. “The homeowner was pretty handy himself. I just supplied some design work and carvings.”

Westley recommends that people interested in getting a CNC shouldn’t just be thinking about the carving they can use the CNC for, but for all the other kinds of things they can produce as well.

“I use both of my DWC units for cutting and mill work as well,” Westley says. “A lot of my business comes from Victorian reproduction items such as profiled flat panel balusters.”

Westley’s DWC5100